RUBBER JOINT VALVE — FLEXIBLE, RELIABLE, AND HIGH-PERFORMANCE SOLUTION FOR MODERN PIPING SYSTEMS

2025-11-27

A rubber joint valve is an essential component for industrial, commercial, and municipal piping systems, designed to provide reliable sealing, vibration absorption, and flexible connection. As piping networks become increasingly complex, and as industries demand durability, safety, and efficiency, rubber joint valves offer a critical solution to common piping challenges. The main framework of a piping system relies not only on rigid pipelines but also on flexible joints that can accommodate thermal expansion, pressure variations, and misalignment. Rubber joint valves combine the functionality of standard valves with the elasticity and adaptability of rubber connectors, offering enhanced operational performance and extended system lifespan.

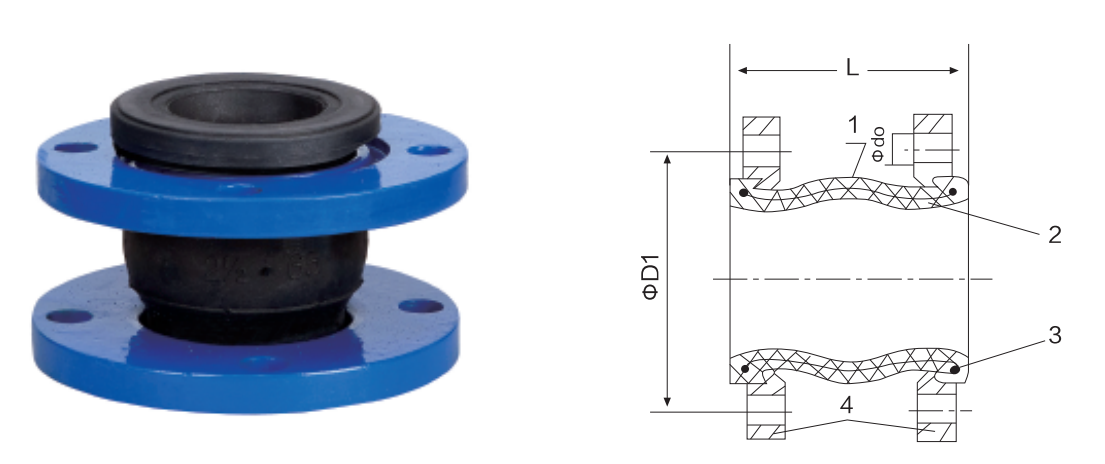

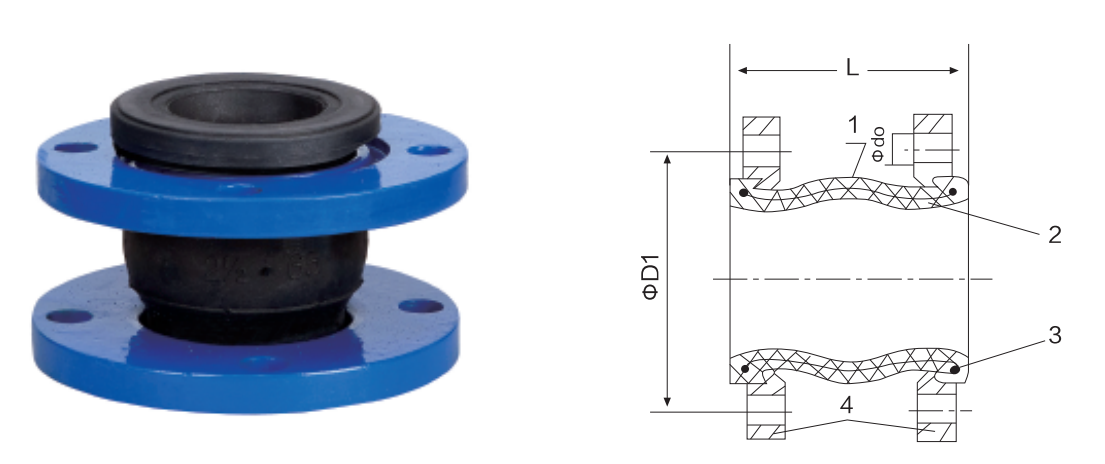

The core structure of a rubber joint valve includes a high-quality rubber sleeve, reinforced with internal fibers or steel rings, integrated with a valve mechanism such as a gate, ball, or butterfly component. The rubber sleeve provides flexibility, allowing the valve to absorb vibrations, compensate for slight misalignments, and reduce stress on the connected pipes. The valve mechanism ensures precise flow control, shutoff capability, and leak prevention under a variety of operating conditions. Advanced designs may include flanged ends or threaded connections for easy installation, ensuring compatibility with multiple piping standards and reducing the complexity of system integration.

One of the major advantages of using rubber joint valves is their ability to reduce leaks and maintenance costs. In traditional rigid piping systems, vibrations, pressure surges, and thermal expansion often lead to joint failure or pipeline damage. The rubber joint valve mitigates these issues by providing a flexible seal that accommodates movement without compromising tightness. This directly addresses a common customer pain point: frequent maintenance and unexpected downtime due to leaking valves or joint failures. By maintaining reliable sealing and reducing mechanical stress, these valves extend the service life of the entire piping system, saving time and costs in the long term.

Another significant advantage is vibration damping and noise reduction. In water supply, HVAC, and chemical processing systems, pumps, compressors, and fluid flow generate vibration that can transfer throughout rigid piping networks, causing noise, fatigue, and even structural damage. Rubber joint valves act as a buffer, absorbing vibrations and minimizing resonance, which protects both the piping system and surrounding infrastructure. This feature is especially valuable in residential buildings, commercial facilities, and sensitive industrial environments where operational noise and equipment longevity are critical concerns.

Rubber joint valves are highly versatile and suitable for multiple applications. In water supply networks, they provide leak-proof connections that withstand pressure fluctuations. In chemical and industrial processing, they resist corrosion, chemical attack, and high-temperature variations. In HVAC systems, they absorb vibrations and allow for thermal expansion, protecting ductwork and piping connections. Real-world applications demonstrate their effectiveness: a municipal water treatment plant installed rubber joint valves to replace aging rigid connectors, resulting in significantly fewer leaks and reduced maintenance. A chemical processing facility utilized rubber joint valves to handle corrosive fluids, ensuring safe operation and consistent flow control. These examples highlight the valve’s ability to solve practical issues related to system integrity, safety, and efficiency.

Ease of installation and adaptability further enhance the rubber joint valve’s appeal. Modular designs allow maintenance teams to replace or upgrade valves without extensive downtime. The combination of flexible rubber sleeves and standard valve mechanisms simplifies integration with existing piping networks, reducing labor costs and project complexity. Users can select appropriate valve sizes, pressure ratings, and materials based on the specific requirements of their system, ensuring optimal performance and long-term reliability.

In addition to practical performance, rubber joint valves contribute to environmental safety and regulatory compliance. By preventing leaks and controlling fluid flow precisely, they reduce the risk of environmental contamination in water treatment, chemical plants, and industrial operations. Compliance with standards for pressure, temperature, and chemical resistance ensures that operations meet safety and environmental regulations, protecting both personnel and surrounding areas.

In conclusion, the rubber joint valve is a versatile, durable, and high-performance solution for modern piping systems. It combines flexible connection, precise flow control, vibration absorption, and leak prevention to enhance the reliability and longevity of water supply, chemical, HVAC, and industrial piping networks. By addressing key pain points such as leakage, maintenance frequency, vibration, and system stress, rubber joint valves provide customers with a cost-effective, safe, and efficient solution. Whether applied in municipal, commercial, or industrial systems, these valves ensure smooth operation, protect infrastructure, and deliver long-term value.

Contact Us

Email:

Tel/WeChat:

Address:

Chenggong Development Zone, Ximei Street, Nan'an City, Quanzhou City, Fujian Province