Gaote Holding Group focuses on the research and development and production of various valves

-

Products

-

-

-

Understanding valve structure (gate valve)

2024-04-12

Gate Valve Definition

A gate valve is a valve that uses a gate or wedge-shaped disc that moves perpendicular to the fluid to open or close the flow of fluid in a pipe.

Gate valves are the most commonly used type of valve in all process equipment and belong to the category of linear motion valves.

In use, it is either fully open or fully closed.

When the gate valve is fully open, the gate is completely out of the fluid path, resulting in almost no flow resistance. Therefore, there is essentially no pressure drop when fluid passes through the gate valve.

To achieve proper sealing, when the valve is fully closed, there needs to be 360° surface contact between the gate and the seat.

Gate valves are not used for throttling or regulating because precise control cannot be achieved.

High-velocity water flow in a partially open valve can cause erosion of the gate and seat surfaces, and generate vibration and noise.

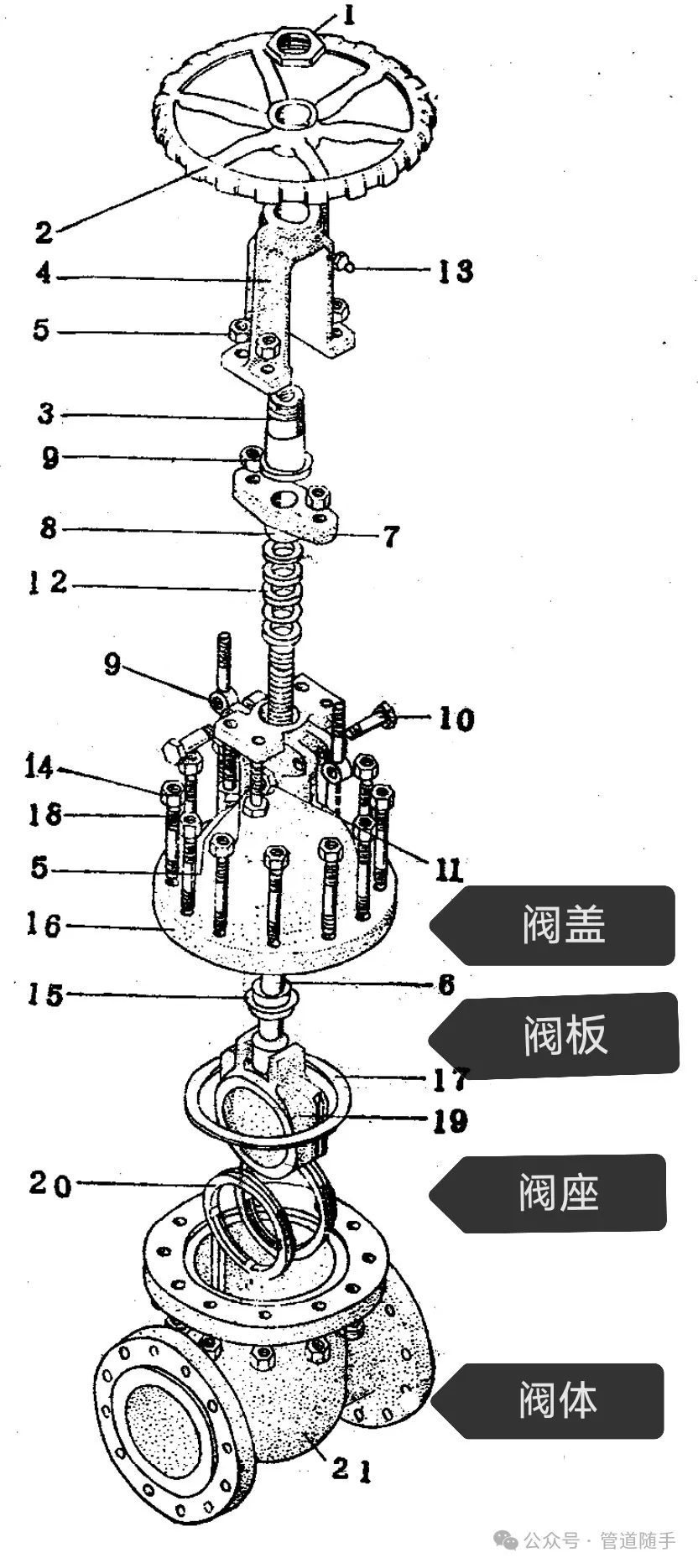

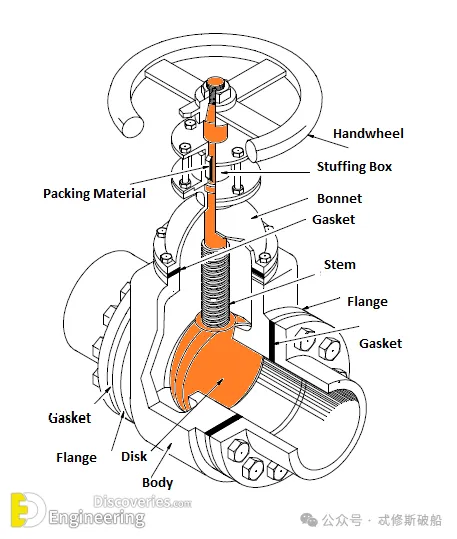

Gate Valve Structure

1. hand wheel nut

2. hand wheel

3. stem nut

4. yoke

5. yoke bolting

6. stem

7. gland flange, packing gland

8. gland

9. gland eyebolts and nut

10. gland lug bolts (eyebolt pin)

11,14. nut

12. stem packing

13. drain plug

15. backseat bushing (bonnet stem bushing)

16. bonnet

17. bonnet gasket

18. bonnet bolts and nuts

19. gate (disc, wedge)

20. renewable seat ring

21. body

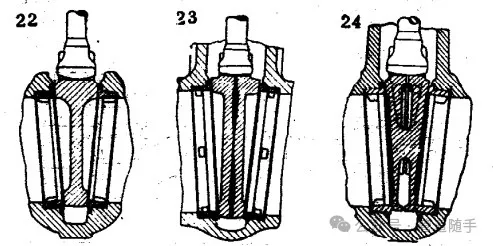

22. solid wedge

23. split wedge

24. flexible wedge

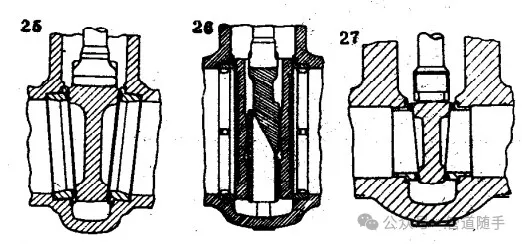

25. Teflon seat ring

26. double disc, parallel seat

27. Teflon insert in seat ring

三 Main Component Functions of Gate Valves

The body is the main part of the valve, holding all the components together. In most cases, it is connected to the pipeline via flanges and gaskets. It is the pressure boundary of the valve.

The bonnet is the second pressure boundary. It is connected to the body via bolts or flanges.

The combination of the stem, seat, and disc is called the valve internals. The performance of the valve depends on the arrangement of the seat and disc.

The seat and disc are the most important parts of the gate valve. It contains a gate and a seat that closely matches the gate.

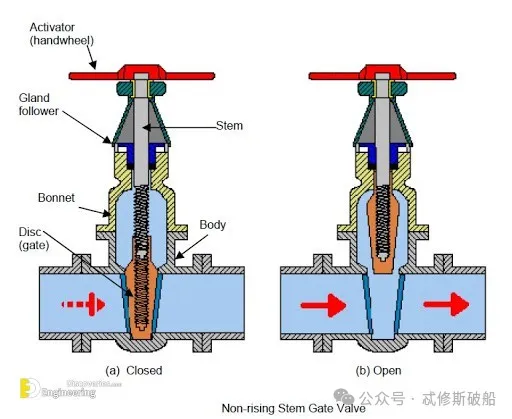

The stem connects the actuator and disc in the gate valve. It allows the disc and seat to be opened and closed. There are two types of stems: rising stem, which rises when the valve is opened; and non-rising stem, which has no vertical movement.

The valve actuator is a hand wheel used to operate the stem and disc.

Types of Gate Valves

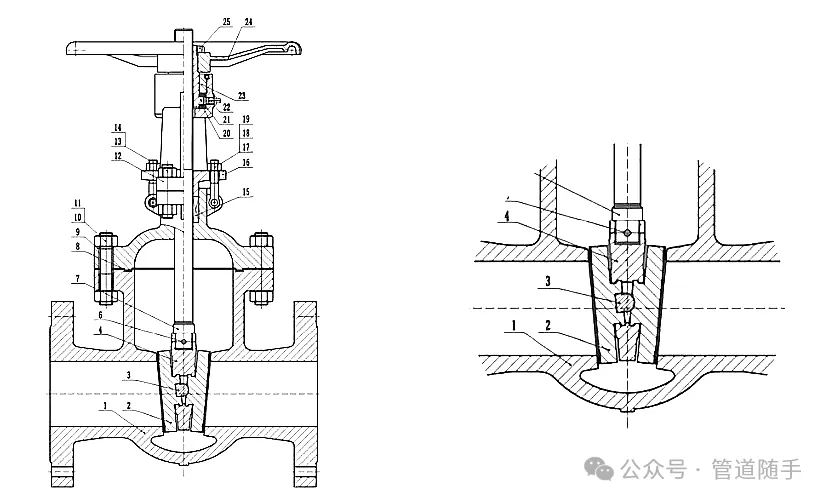

1) Solid wedge gate valve

This is a very popular type of gate valve. It is suitable for almost all materials. A wedge disc is used here, which is fitted onto the seat. It is suitable for medium pressure conditions but not for high pressure conditions because it can get stuck due to high pressure, leading to leakage. Sometimes, due to thermal expansion, the seat cannot be opened and gets stuck. This phenomenon is called thermal binding. 。

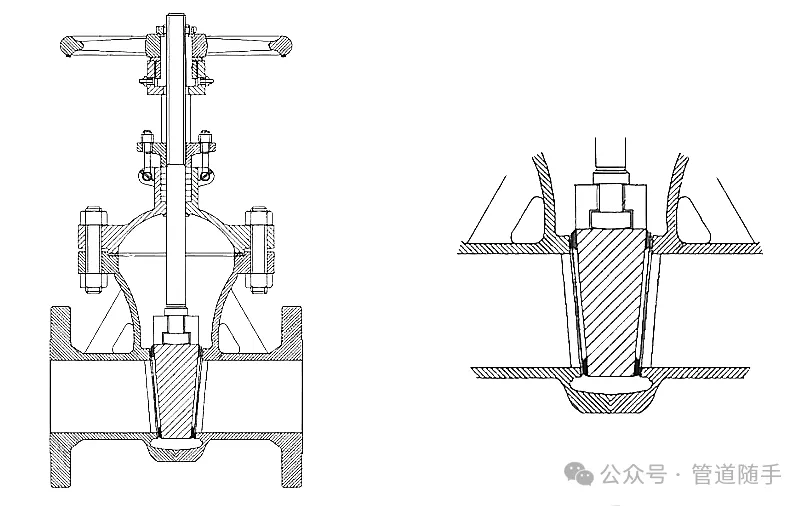

2) Parallel disk or Split gate valve

This type overcomes the problem of thermal binding due to its free movement. Here, two discs and the seat are held together by springs. It is suitable for low and medium pressure applications. 。

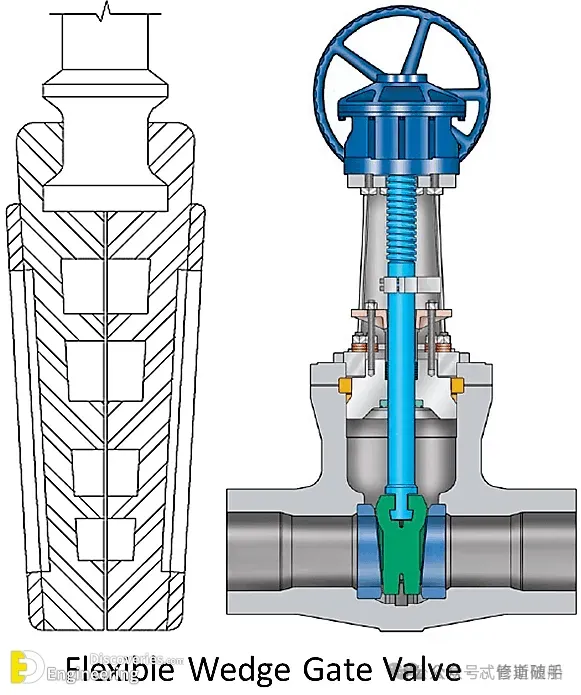

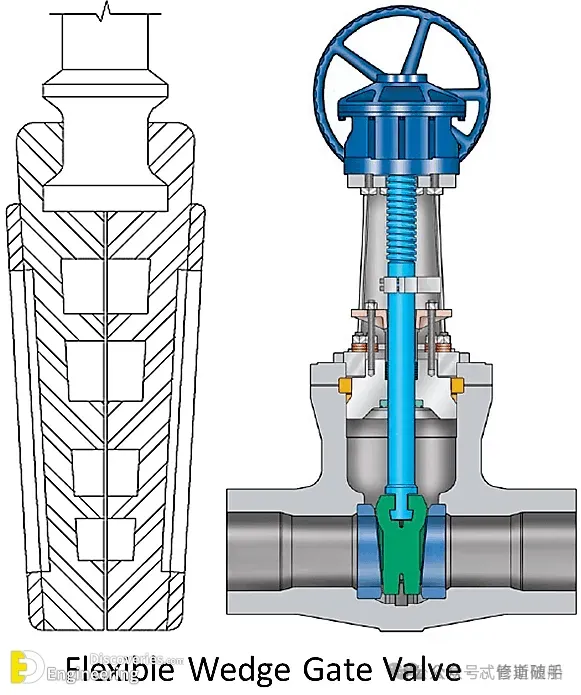

3) Flexible wedge gate valve

It has a small cut on the disc that mates with the seat. With this cut, there is no leakage between the seat and the disc. It is used in steam applications. 。

4) Non-rising and rising stem gate valve

In a rising stem gate valve, the stem rises when the gate valve is opened and falls when it is closed. In a non-rising stem gate valve, the stem does not move vertically, and is used when space is limited. 。

Advantages and Disadvantages of Gate Valves

Low resistance to fluid flow

Can be used for slurries and viscous liquids

Easy to maintain

Opening and closing is very time-consuming

Throttling is very poor

Previous:

Contact Us

Email:

Tel/WeChat:

Address:

Chenggong Development Zone, Ximei Street, Nan'an City, Quanzhou City, Fujian Province

Gaote Holding Group Co., Ltd.

Tel: +86-595-8896-8800

Email: gaotegroup@126.com

Address: Chenggong Development Zone, Ximei Street, Nan'an City, Quanzhou City, Fujian Province

Leave a message

* Note: Please be sure to fill in the information accurately and keep the communication open.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.