Product Features Product feature

●Low flow resistance: The streamlined valve body, plus the valve seat flow area is more than 1.4 times the pipe flow area, so when the valve flap opening travel angle is 40 degrees, the full flow field can be achieved, and the flow resistance is quite small.

·Extremely low opening and closing pressure difference: Low full-open flow velocity, due to the valve flap's oblique large eccentricity design, plus the double shaft adopts a fixed type, so the seal at the shaft seal is reliable. The valve body and shaft are connected by a hinge, with self-lubricating

sliding bearings, minimizing friction. Therefore, the opening and closing pressure difference can be less than 2 meters of water column, and the full-open flow velocity is about 2 m/s, much lower than other rotary lift type check valves, and it is not easy to jam in sewage media.

·Good sealing performance: The conical surface sealing design of the valve seat allows the valve flap to self-lock after closing and can achieve reliable sealing under back pressure. Experiments show that even after 100,000 opening and closing cycles, its sealing performance still meets and exceeds the check valve leakage index.

●Excellent dynamic characteristics: Due to the above structural characteristics, when the water flow reverses, the valve flap responds quickly,

plus a smaller travel angle of 40 degrees and large-diameter water flow diversion, the impact force of the valve flap on the buffer

device is minimized, and with a buffer cylinder, it greatly reduces water hammer when the pump stops, and at the same time achieves silent

closing.

·Long service life: The unique metal-to-metal, double-confidence oblique design allows the valve flap to quickly disengage from the valve seat when opening, the frictional torque is extremely small, effectively protecting the sealing surface, and the static shaft design also makes the valve flap

during the opening and closing process is only the friction of the bearing,

Technical Parameters Technical Specification

Nominal Diameter DN ( mm )

|

DN200~DN2000mm

|

||

Nominal Pressure PN

|

ANSI 125Lb 150Lb 250Lb JIS7.5K 10K 16K 20K

|

ENPN10 PN16 PN25 BSPN10 PN16 PN25

|

GB PN10 PN16 PN25

|

Main Parts Material Parts Material

Part Name

|

Material Material |

Part Name

|

Material Material |

Valve Body Body

|

Ductile Iron

|

Valve Seat Seat |

Stainless Steel SS

|

Valve Valve Disk |

Ductile Iron

|

Valve Shaft Valve Shaft |

Stainless Steel SS

|

Valve disc seat ring

|

Stainless Steel SS

|

Hydraulic buffer

Hydraulic buffer system

|

Assembly

|

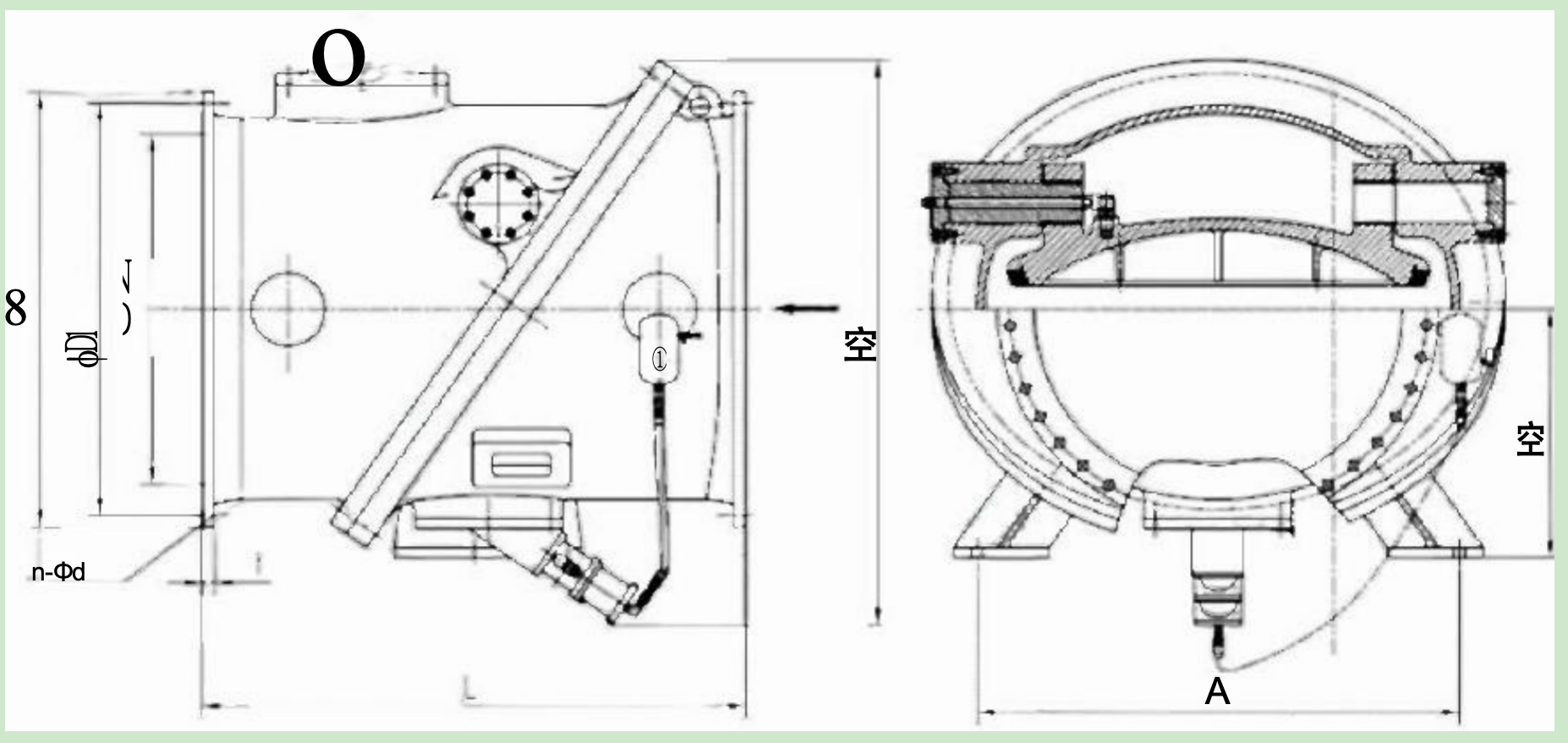

Main External Dimensions and Connection Dimensions Main external dim ensions and connection dimensions(mm)

DN

|

D |

D1

|

t |

L |

H1

|

H2

|

A |

n-φd

|

||||

1.0

|

1.6

|

1.0

|

1.6

|

1.0

|

1.6

|

1.0

|

1.6

|

|||||

500

|

670

|

715

|

620

|

650

|

26.5

|

31.5

|

812

|

1000

|

395

|

763

|

20-28

|

20-34

|

600

|

780

|

840

|

725

|

770

|

30

|

36

|

965

|

1185

|

450

|

860

|

20-31

|

20-37

|

700

|

895

|

910

|

840

|

840

|

32.5

|

39.5

|

1130

|

1237

|

525

|

1000

|

24-31

|

24-37

|

800

|

1015

|

1025

|

950

|

950

|

35

|

43

|

1320

|

1430

|

608

|

1164

|

24-34

|

24-40

|

900

|

1115

|

1125

|

1050

|

1050

|

37.5

|

46.5

|

1320

|

1600

|

670

|

1250

|

28-34

|

28-40

|

1000

|

1230

|

1255

|

1160

|

1170

|

40

|

50

|

1565

|

1760

|

750

|

1400

|

28-37

|

28-43

|

1200

|

1455

|

1485

|

1380

|

1390

|

45

|

57

|

1750

|

2000

|

860

|

1660

|

32-40

|

32-49

|

1400

|

1675

|

1685

|

1590

|

1590

|

46

|

60

|

1925

|

2400

|

1050

|

1925

|

36-43

|

36-49

|

1600

|

1915

|

1930

|

1820

|

1820

|

49

|

65

|

2368

|

2700

|

1070

|

2097

|

36-43

|

40-56

|

1800

|

2115

|

2130

|

2020

|

2020

|

52

|

70

|

2590

|

2750

|

1185

|

2175

|

44-49

|

44-56

|

2000

|

2325

|

2345

|

2230

|

2230

|

55

|

75

|

3050

|

2950

|

1335

|

2425

|

48-49

|

48-62

|

Keyword

Tilting-plate hydraulic buffer check valve

Professional valve manufacturing

Contact Us

Belongs to: