Product Series

Contact Us

Email:

Tel/WeChat:

Address:

Chenggong Development Zone, Ximei Street, Nan'an City, Quanzhou City, Fujian Province

Flow valve series

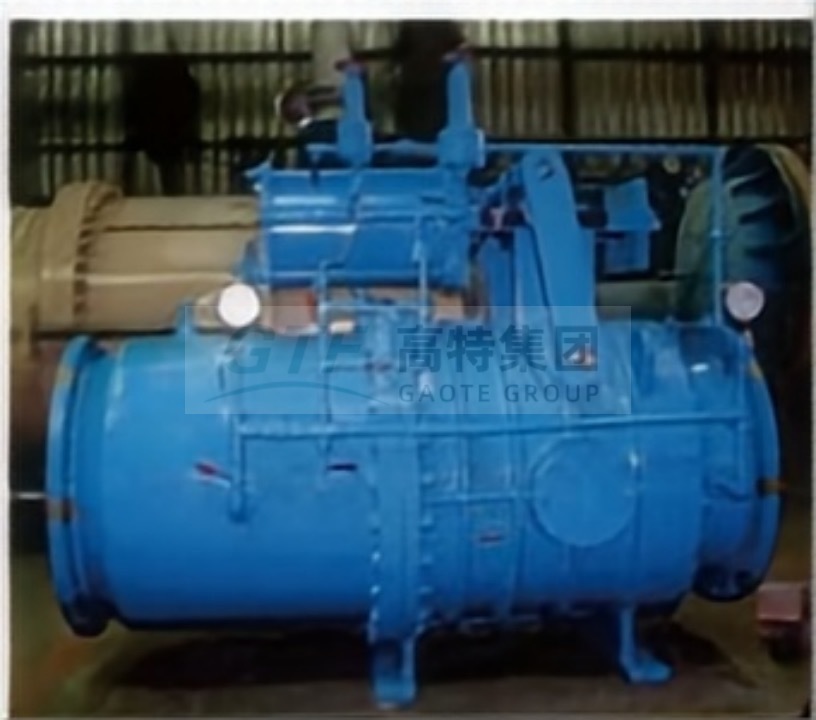

Bimetallic seat ball control valve

Product Overview

The double metal seated ball valve adopts a fixed axis double seat design, and its excellent performance is used for pump control, flow control, high pressure differential venting, main line shut-off and other occasions. Its hydraulic loss is similar to that of a branch pipe section, saving users a large amount of water energy. The stability during high pressure differential throttling, erosion resistance and unique flow curve can meet various high-requirement working conditions. With a double metal seat design, the service life can be up to more than 10 years. The metal seat is not scratched, stuck or rubbed when opening or closing. The metal seat can be used in any environmental liquid. The metal seat can be precisely controlled for flow regulation, pressure regulation, sewage, and pump outlet. The valve body structure can withstand super strong fluid impact force. The valve body structure has superior strength and ductility compared to ordinary cast iron. The full flow path valve design has a pressure loss equal to the length of the pipe diameter, and the 100% water flow path is unobstructed.

Tilting-plate hydraulic buffer check valve

Product Overview

The Tilting Disc Check Valve is a true full-flow design, with a short closing stroke and fast closing speed. 90% of the stroke is a fast closure, and 10% is a slow closure. The slow closing time can be adjusted via a buffer device. By adjusting the appropriate closing speed, the impact of water hammer on the pump and pipeline can be reduced. Due to its extremely low water loss and excellent closing dynamic characteristics, the tilting disc check valve is the best check valve among the rotary valves. The product is widely used in water plants, power plants, metallurgical and petrochemical industries, and water supply and drainage systems. It is generally used in water pumps and reservoirs to prevent backflow from the reservoir and damage to the water pump.

Product overview

The ZXF fixed cone valve is a discharge valve suitable for high-head, large-flow conditions, which operates without vibration or cavitation. It is commonly used in the following systems:

Spillway valves for hydropower generator units (bypass free discharge valves);

Spillway valves for reservoir dams;

Flow control valves for reservoir water supply pipelines;

Pressure regulating valves in various zones of municipal water supply systems;

It is particularly suitable for safe discharge in pipeline systems under zero back pressure and high-velocity cavitation conditions.

Piston type flow control valve

Piston type flow control valve adopts national standard flange connection (GB/T 9119) and piston type regulating structure, integrating manual/electric dual drive mode, with adjustment accuracy up to ±2%, suitable for multiple media such as water, sewage, and oil. The valve body adopts ductile iron (GB/T 12227) for pressure resistance and corrosion resistance, and the sealing system meets the requirements of GB/T 12238. It is widely used in water supply and drainage, heating, power, chemical industry and other fields, providing a stable and efficient solution for pipeline flow and pressure control, and is a national standard compliant core equipment for energy saving and safe operation of engineering systems.

Piston type flow control valve

Product Overview

The piston control valve mainly consists of valve body, valve seat, piston, valve stem, crank, connecting rod, drive pin, cone pin bearing and operating mechanism. The piston control valve converts the rotation of the valve stem into the axial movement of the piston along the guide rail through the crank connecting rod mechanism. In the process of the piston moving back and forth, the flow area between the piston and the valve seat is changed to achieve flow regulation and pressure control. Water flows into the valve body from the axial arc shape, and the flow path in the piston control valve is axially symmetrical, so that no turbulence will be generated when the fluid flows through. No matter where the piston moves to, the water flow section in the idle cavity is annular, and converges towards the axis at the outlet, so as to achieve the best cavitation prevention and avoid the damage to the valve body and flow path caused by throttling.

The flow switch uses a national standard flange connection (GB/T 9119) and a ductile iron body (GB/T 12227), integrating a high-precision sensor and electronic display unit. The flow monitoring accuracy reaches ±2% FS, and the protection level is IP65. It is suitable for various fields such as fire protection, water supply and drainage, heating, and industrial cooling. It monitors fluid flow in real time and outputs switching signals, providing reliable protection for the safe and efficient operation of the system. It is a national standard compliant core component for industrial and civil pipeline flow control.

Gaote Holdings LLKG-16Q flow switch uses national standard flange connection (GB/T 9119) and ductile iron body (GB/T 12227), integrating high-precision sensing and electronic display unit. The flow monitoring accuracy reaches ±2% FS, and the protection level is IP65.

Suitable for fire protection, water supply and drainage, heating and other fields, it monitors the flow of the medium in real time and outputs switching signals to ensure the safe and efficient operation of the system. It is a national standard compliant core component for industrial and civil pipeline flow control.